Part 4 - Assembling the internals

- Prepare and tune the stabilizers needed for your preferred layout, if not done already.

Prepare and lube the switches as well. - Mount the stabilizers onto the PCB using the provided shims to fill the gap on the thin PCB.

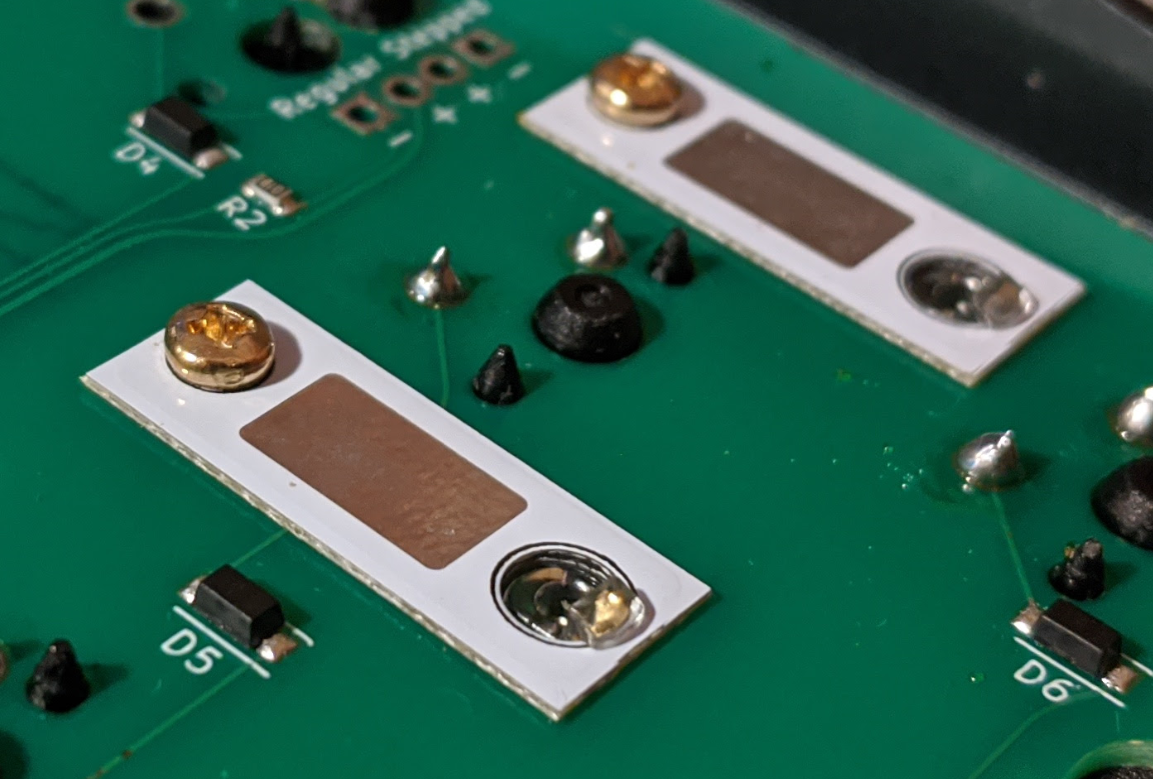

The side with the copper artwork should face away from the PCB.

An example of shim use is shown below; the shim goes on the bottomside of the PCB, with the hook of the stabilizer hooking both the shim and the PCB.

Note: The pictured shim is an earlier revision; however, its usage remains the same.

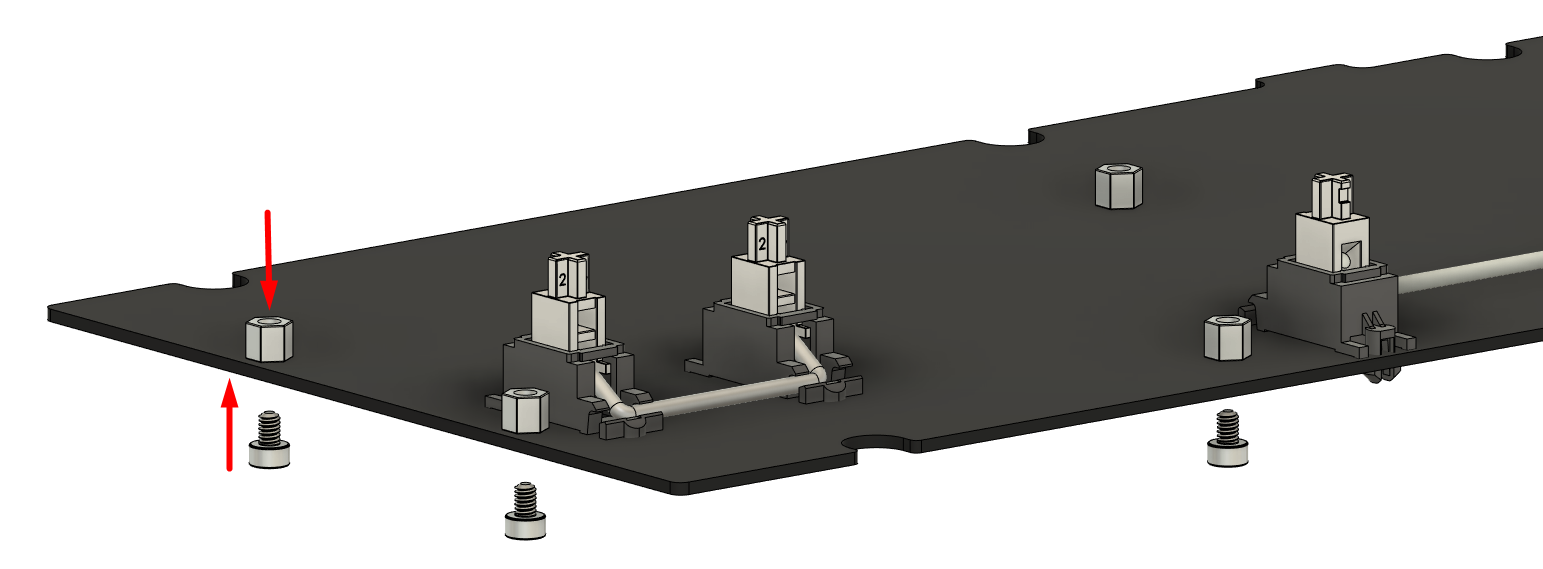

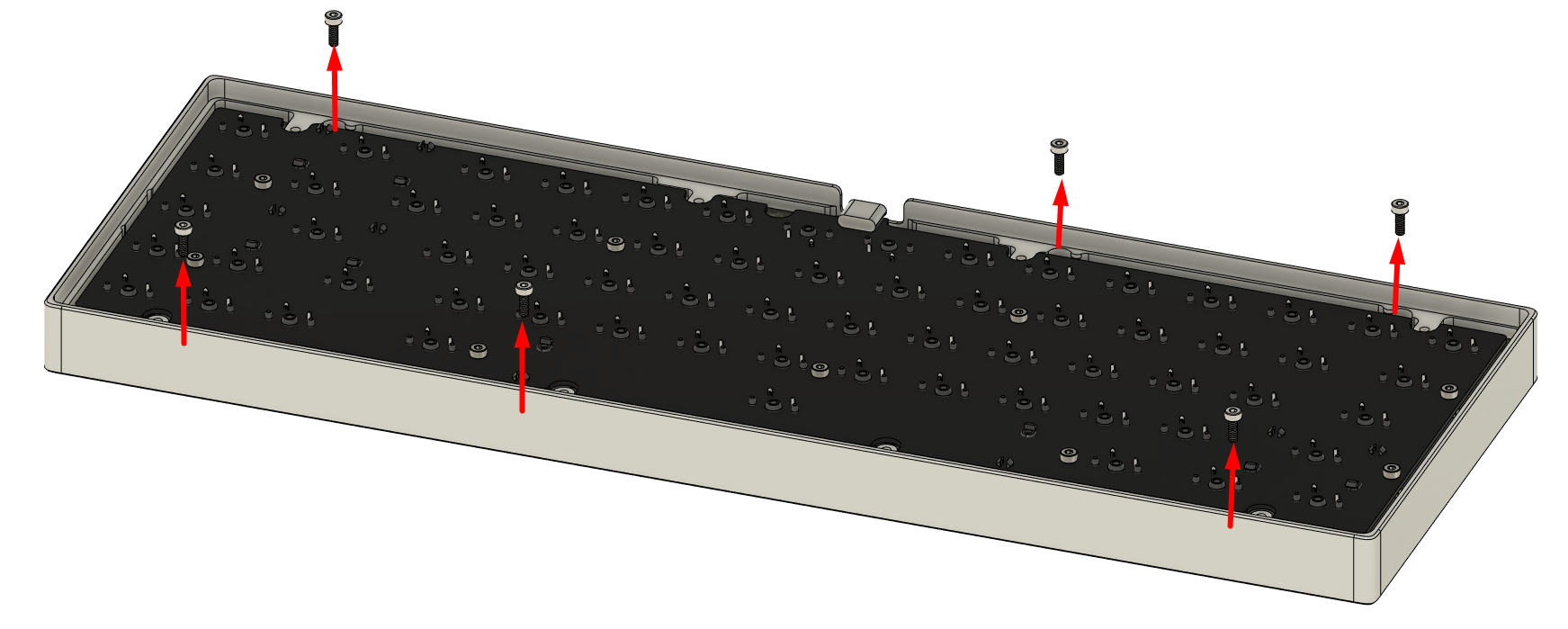

- Open the pack of hotswap standoffs and screws.

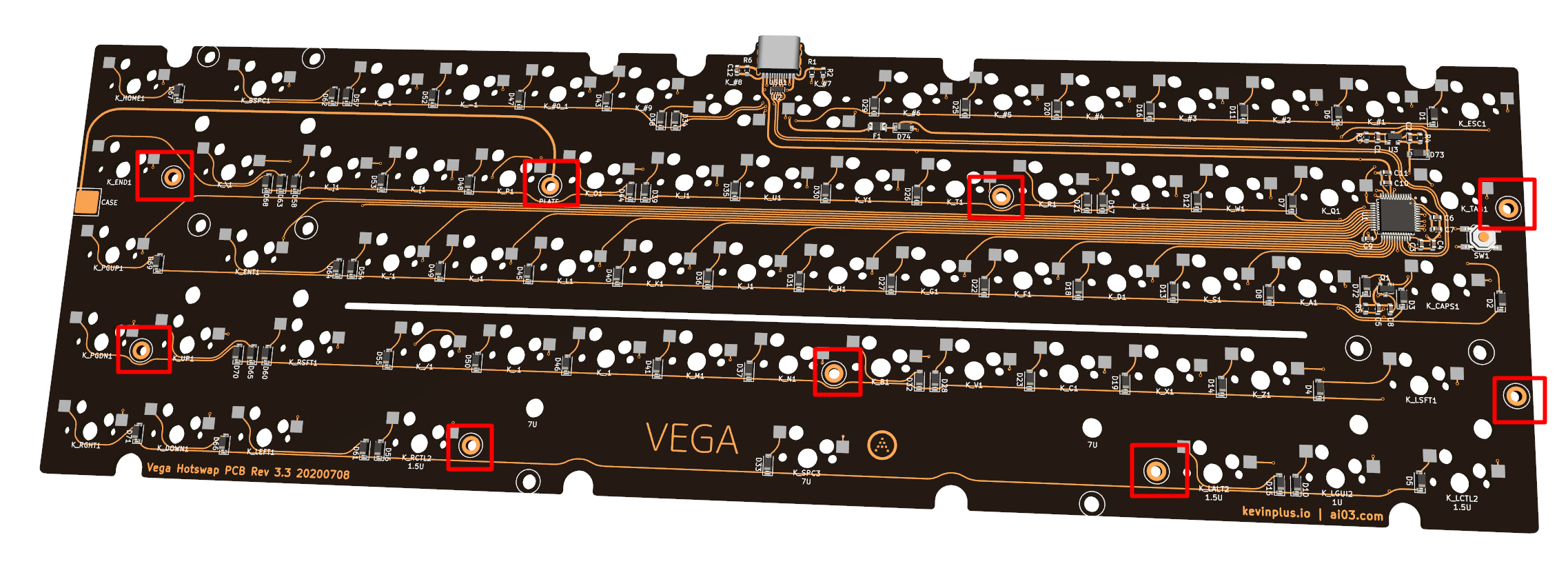

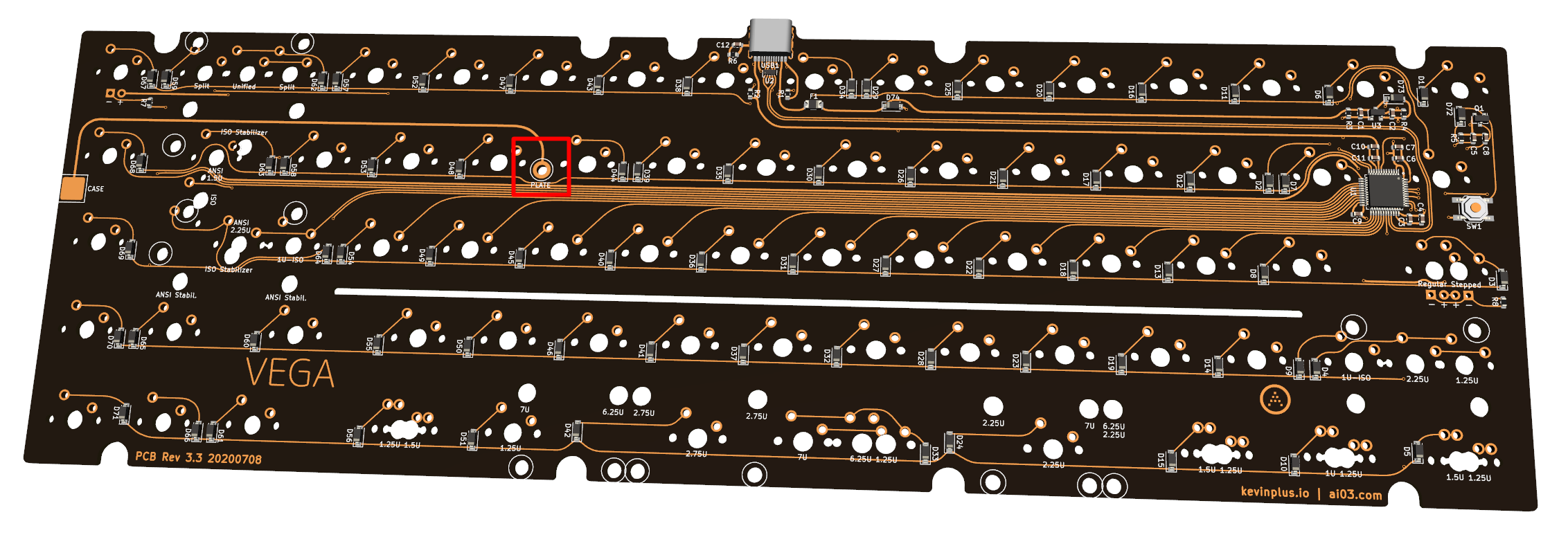

For hotswap users: Install a standoff at each of the 9 standoff screw holes on the PCB, and secure using the short hotswap screws from the bottom.

For soldered PCB users: Install one standoff at the standoff screw hole on the PCB, and secure using a short hotswap screw from the bottom. This is necessary to properly handle static discharges that occur against the plate.

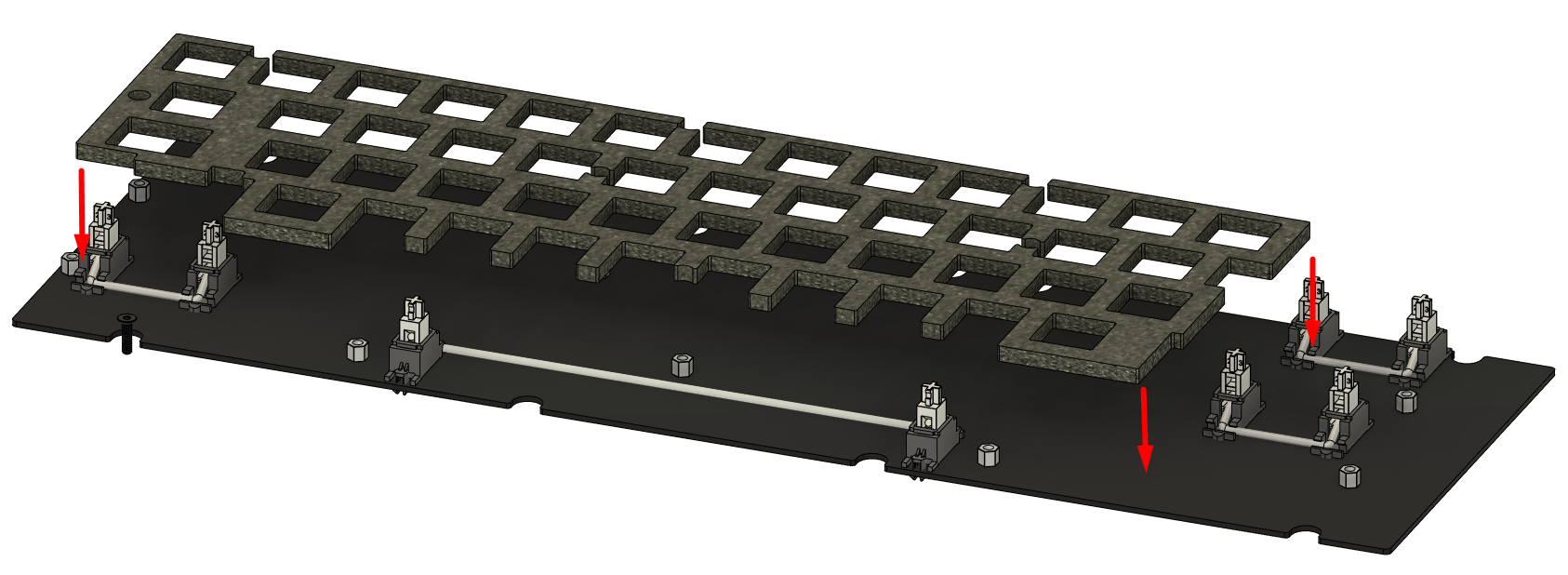

- If you plan to use the foam midlayer, install it above the PCB at this stage.

Our personal recommendation is to install it; if you dislike it, it is always possible to rebuild it without on the hotswap variant.

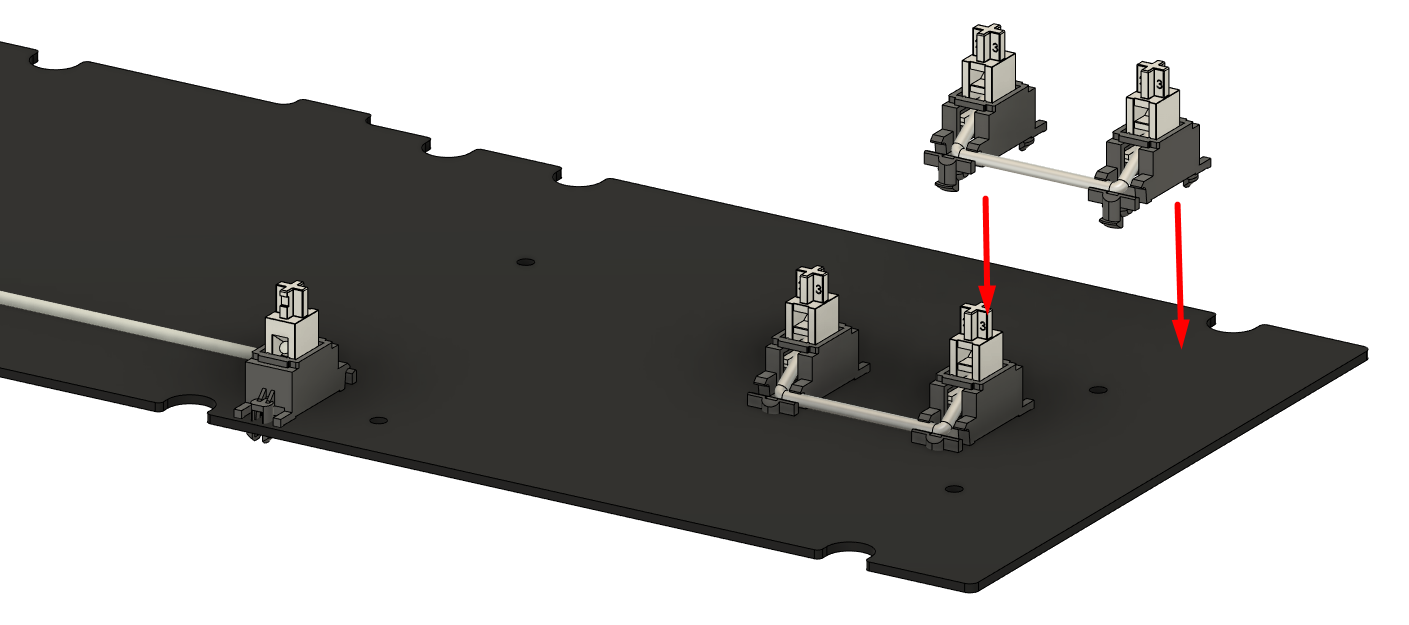

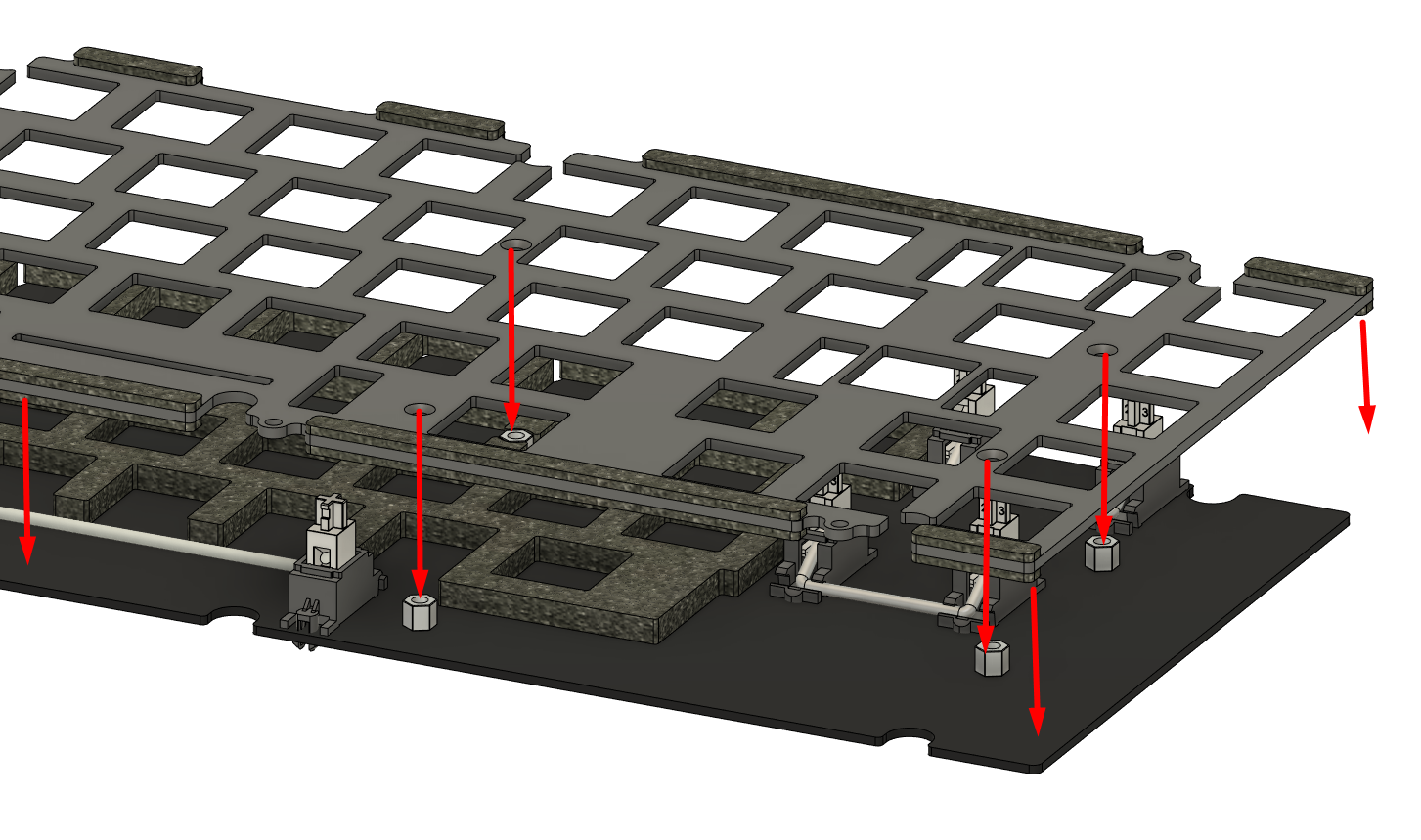

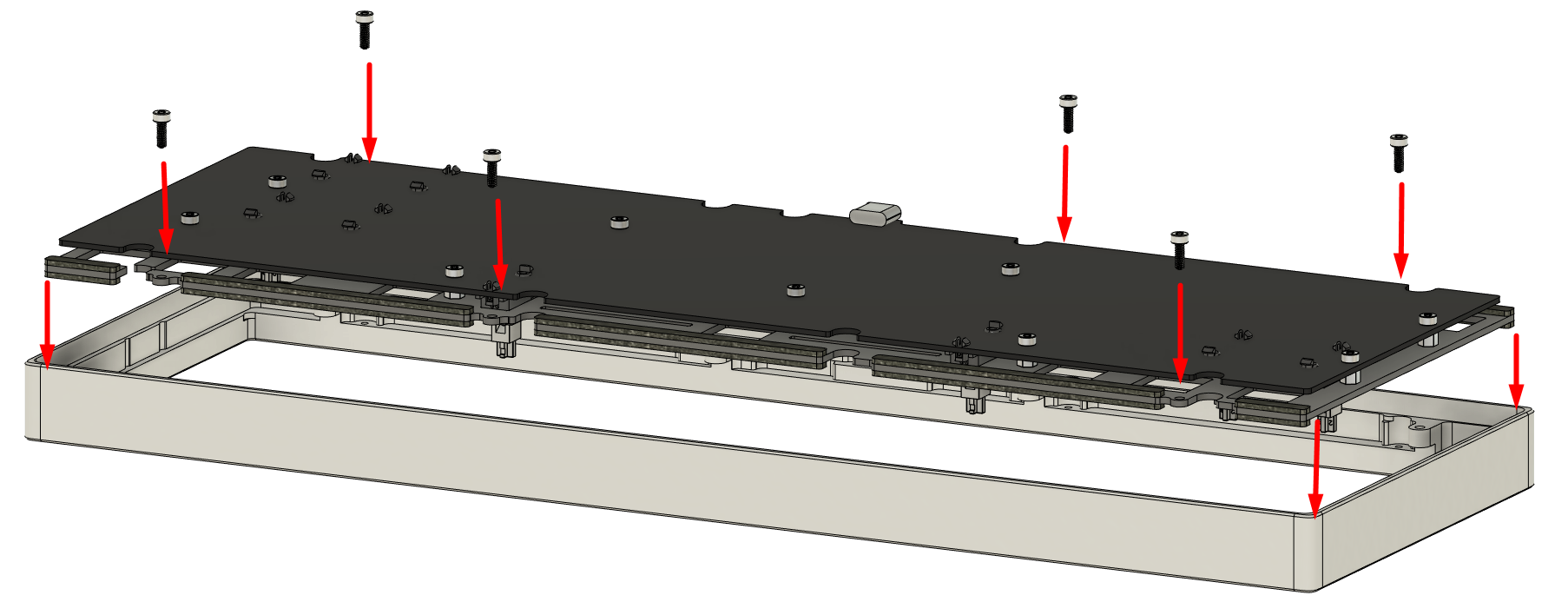

- Install the plate so that the screw holes on the plate align with the standoffs installed onto the PCB.

- Secure the plate to the standoffs using the countersunk hotswap screws.

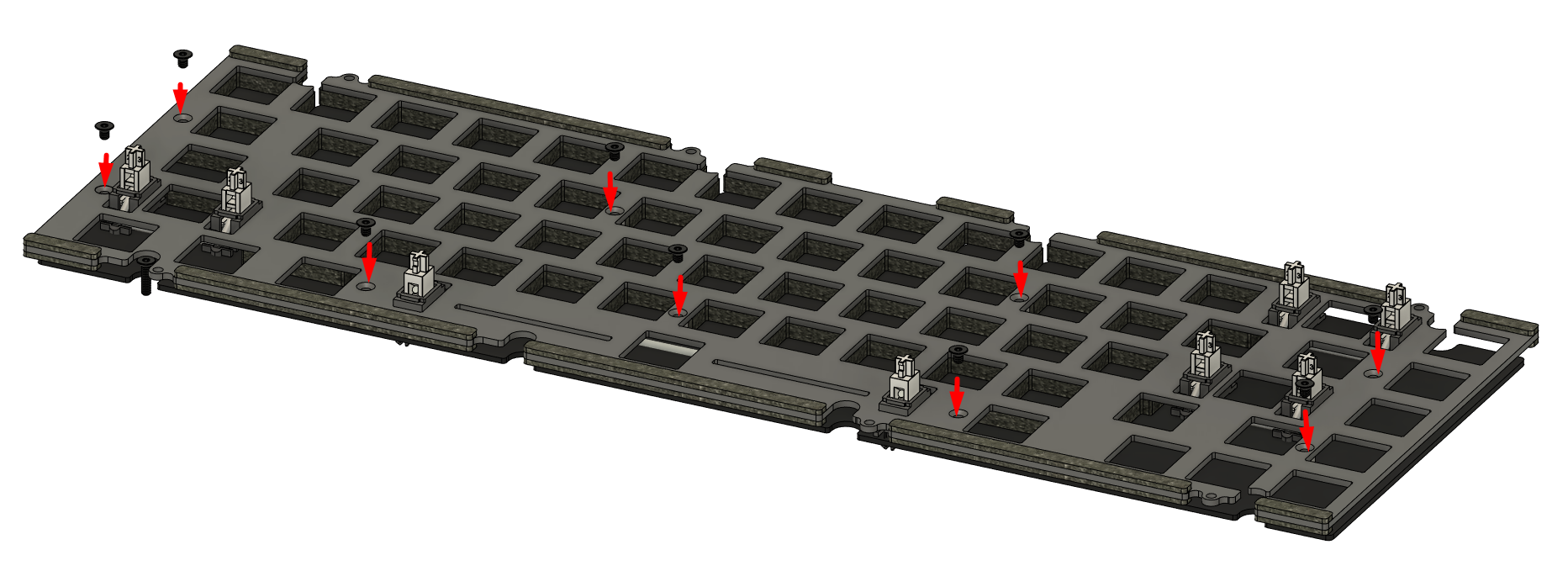

- Place the assembled plate-PCB structure into the top case half, making sure that the plate goes within the vertical rectangular gaskets placed onto the top case half.

Secure this structure to the top using the temporary plate screws.

- Prepare to install switches.

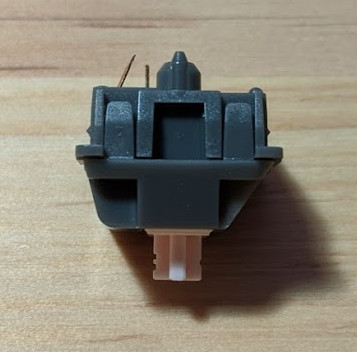

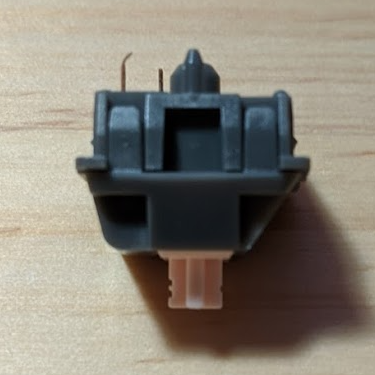

First, take the switch and flip it upside down.

Check for any sort of bent legs, and repair them by bending them back to be perfectly straight.

The following are examples of switches with bent legs.

Notice how the one on the right has a bent tip despite the rest of the leg being straight.

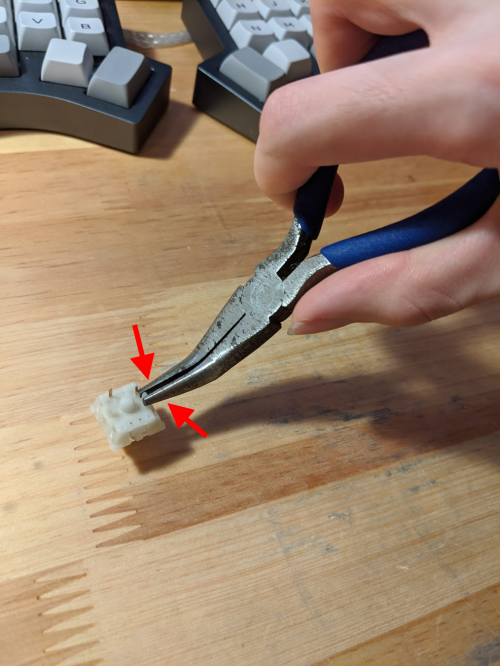

- Some switches are known to have very thick PCB-mount legs which exceed MX spec heavily, such as Gaterons.

For these switches, it is highly recommended to thin the legs by compressing them with flat head pliers prior to installation.

This can be done by closing the pliers against a leg and twisting it around to crunch the leg down.

Note: Do not apply forces so extreme that the switch shatters.

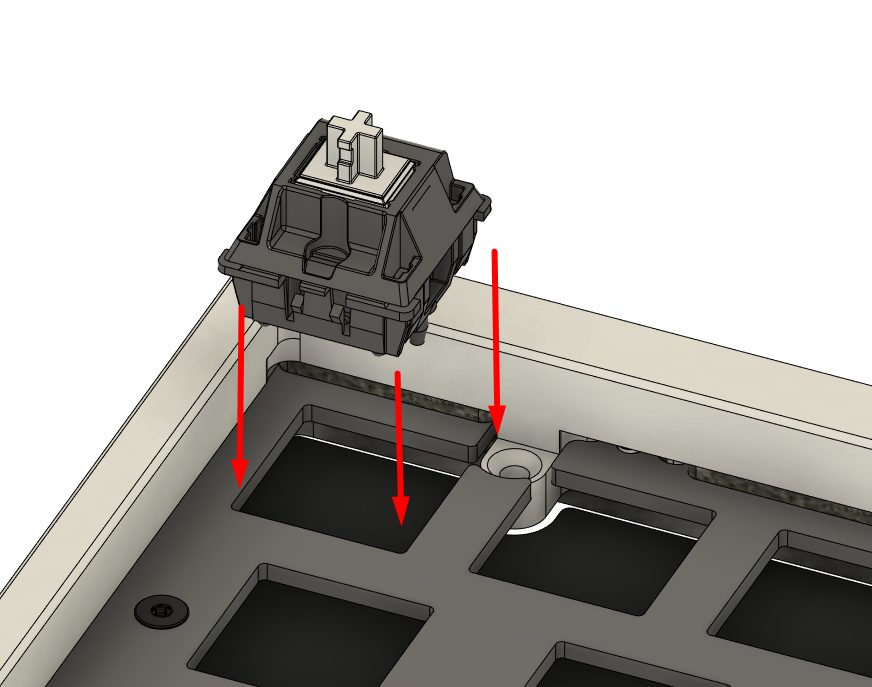

- After un-bending the legs with fingers, tweezers, flat pliers, or your tool of choice, carefully insert them to the plate-PCB structure.

Hold the PCB surrounding the switch and push the switch firmly down, making sure that the switch snaps into the plate and is firmly seated against the PCB.

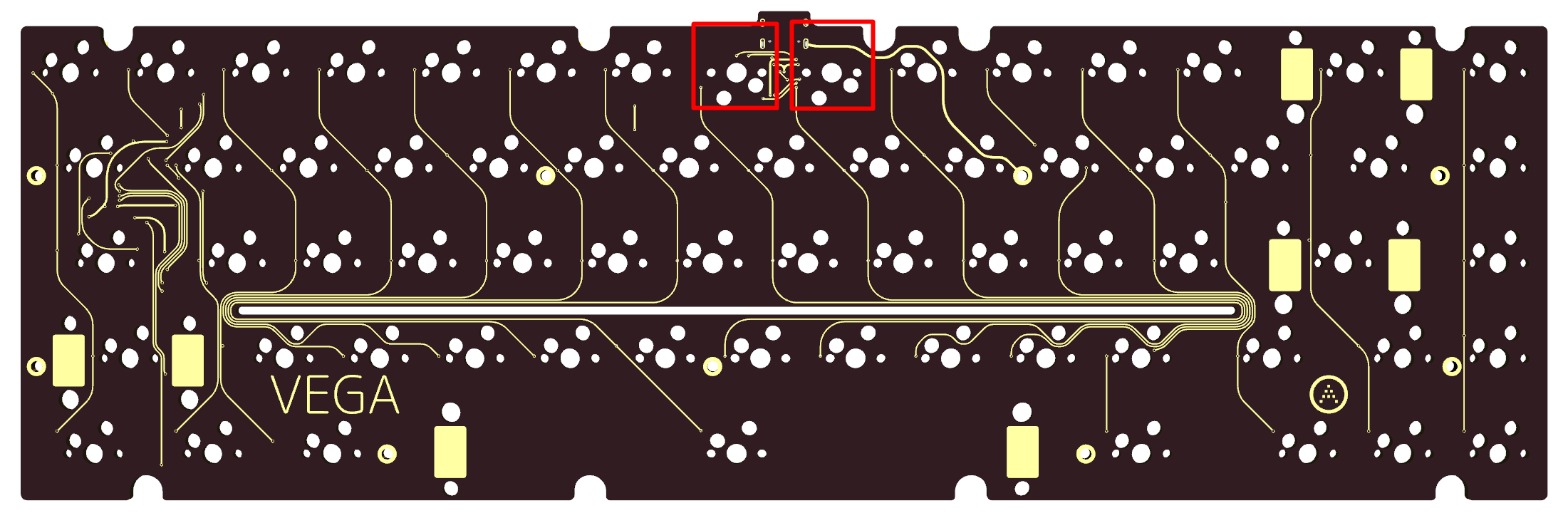

Make sure the orientation is correct: On the hotswap PCB, the keys 7 and 8 next to the USB connector are flipped to avoid obstructing the USB port.

- Repeat steps 7~9 for all switches.

If assembling a hotswap kit, solder the switches. Make sure that the switch is seated firmly against the PCB once soldered.

- At this stage, it is highly recommended to connect the build to a computer and to verify that all keys send a keystroke.

- Flip the structure over, and remove the temporary plate retention screws.

Leave the assembly upside-down at this stage.

That was a lengthy section, but most of the hassle is out of the way.

Now to complete the assembly.